Preparing the Molds for Carbon Fiber Layups

By Mechanical Team | November 16, 2024

Before we could proceed with the carbon fiber layup process, we had to ensure that the molds were perfectly prepped. This involved a careful series of steps to ensure the molds were smooth, free from imperfections, and ready for the layup. We began by sanding the molds to eliminate any rough edges or inconsistencies from the 3D printing process. Once the surface was smooth, we coated the molds with a release agent, which would allow for easy removal of the carbon fiber components after curing. To ensure an even and flawless finish, we sanded the molds again and applied additional layers of release wax to further improve the mold’s smoothness and provide extra protection. These preparation steps were crucial for achieving high-quality, precision components when we moved on to the layup process.

Key Achievements:

- Sanded and coated the 3D printed molds to ensure smooth surfaces for carbon fiber layup.

- Applied release agents and wax to ensure easy component removal and a flawless finish.

- Enhanced mold quality for precise and high-performance aerospace components.

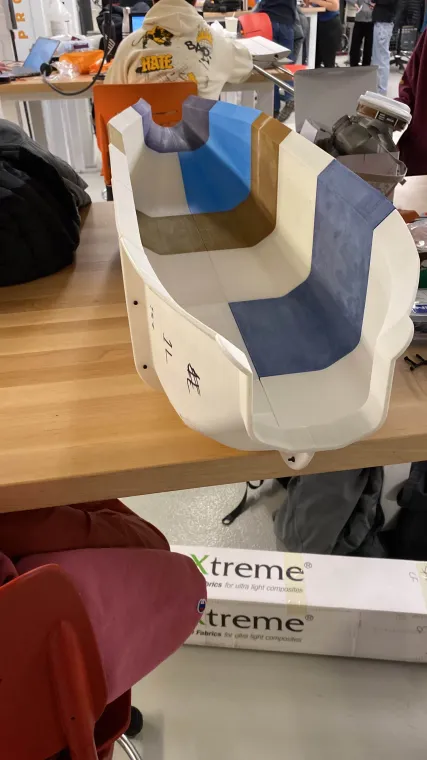

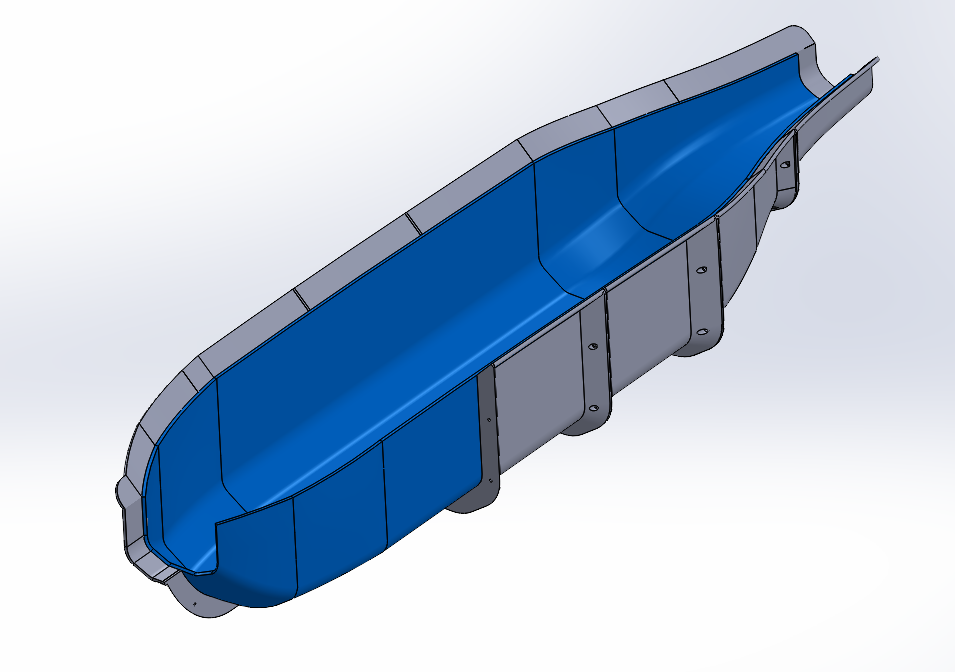

Image Gallery:

Fuselage bottom mold 3D prints