Carbon Fiber Layups: Building Strength into the Wings and Tail

By Mechanical Team | December 14, 2024

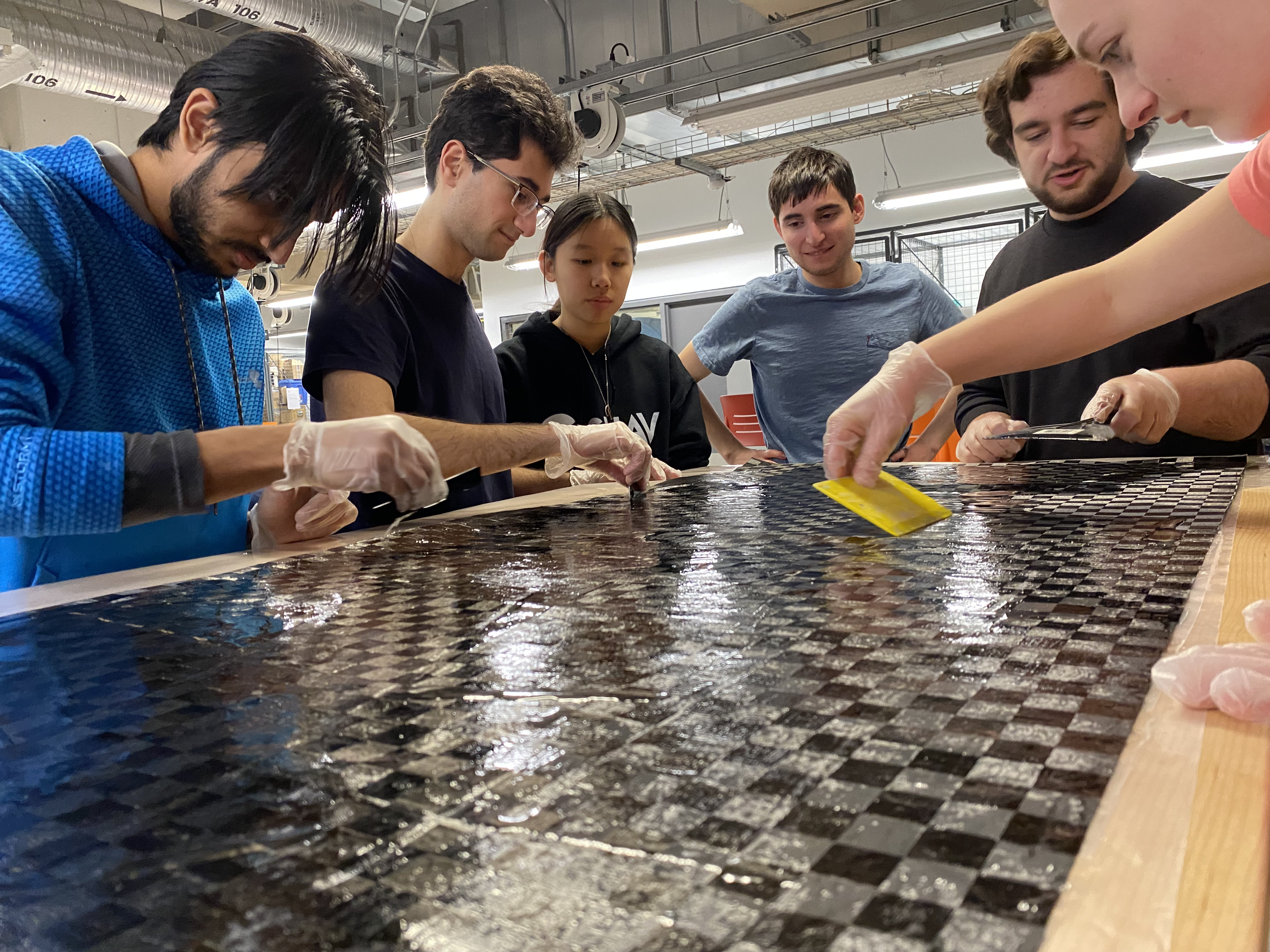

Prepping the wings for the layup by embedding servo wires (for ailerons) and covering grooves with foam putty

After preparing the wings and tail surfaces, we moved on to one of the most exciting phases: the carbon fiber layup. This process began by embedding the servo wires for the ailerons and sealing any grooves with foam putty to ensure a smooth surface. We carefully measured out the carbon fiber sheets, cutting them to the perfect size for the wing layups. Once the fabric was ready, we added the aluminum ribs to the main wing, gluing them between the two sections, and positioned carbon fiber spars (tubes) inside the wings for added structural integrity. Next, we soaked the carbon fiber sheets in epoxy resin, which would bond the fibers and provide the strength needed for the aircraft. The resin was then spread evenly over the carbon fiber, and the entire assembly was placed in a vacuum bag under pressure to cure. This process not only ensured that the wings and tail would be both lightweight and robust, but it also demonstrated the power of composite materials in aerospace engineering.

Key Achievements:

- Embedded servo wires and sealed grooves in preparation for the wing layups.

- Manufactured and installed aluminum ribs and carbon fiber spars to enhance wing structure.

- Applied epoxy resin to carbon fiber sheets and cured them under vacuum pressure for optimal bonding.

- Achieved a balance of lightweight and structural strength in the wings and tail surfaces.

Image Gallery:

Measuring out the carbon fiber for the wing layups

Cutting out the mylar layer

Measuring out epoxy resin

Pouring & spreading the resin over the carbon fiber